The double axle Groundhog Mobile Welfare Unit GP500D is a lightweight and compact towable unit that meets HSE requirements and provides all your on-site needs in one small package.

The units are suitable for accommodating ten persons, which provides pleasant and safe working environments, ideal for rental companies and contractors. Easily towed, one man operation secured and manoeuvred on site, in less than 3 minutes. Its’ many safety features make it a high secure and money saving choice of welfare unit for rental companies and contractors.

The Eco Fusion Mobile units from Groundhog are suitable for accommodating twelve to fourteen persons, which provides pleasant and safe working environments, ideal for rental companies and contractors.

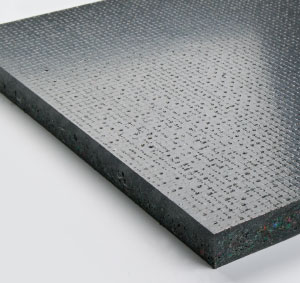

Steel construction forms one of the most secure welfare units on the market.

Groundhogs unique lowering system which enables the unit to be secured at ground level when sited. This also enables a safe entry and exit by personnel without the requirement for steps.

Steel personnel doors with built in locking mechanism and hidden hinges.

The windows are protected by steel shutters, which are locked internally and can only be opened from inside the rest room.

The nosecone security cover is a swing operated hood which protects the towing coupling and once locked, prevents the unit from being removed off site.

Push button controls to lower front and rear hydraulic rams

Rams lift unit from ground ready to release axle pins

Unit is lowered and canopy locked to protect towing facility

These include sanitary conveniences, washing facilities, access to drinking water, accommodation for drying and changing clothes, and an area for rest and eating.

Groundhog welfare units are supplied with a current electrical installation test certificate.

| Dimensions | 5000mm(L) x 2300mm(W) |

|---|---|

| Dimensions Inc. Drawbar | 6320mm(L) x 2300mm(W)* |

| Unladen Weight | 2,300kg* |

| Possible Gross Weight | 3,000kg* |

| Generator | 6kVA |