If you require secure welfare and office space then the Standard SWO7600 is an ideal static unit. Along with the SW6100 Standard, it meets HSE requirements, offers anti-vandal features which include a steel personnel double locking door systems and internally secured steel window shutters, providing all your on-site needs in one compact, cost effective package.

The units are suitable for accommodating eight people, providing a pleasant on-site worker welfare environment but it also offers a separate spacious office for managerial/ administration personnel, ideal for rental companies and contractors.

Once lifted into position, they provide a vandal resistant facility and can come with a number of additional money saving features.

The Static units from Groundhog are suitable for accommodating eight persons, which provides pleasant and safe working environments, ideal for rental companies and contractors.

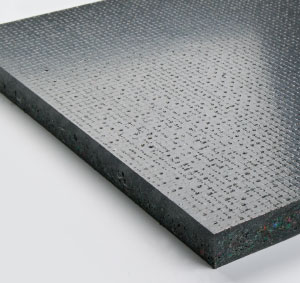

Steel construction forms one of the most secure welfare units on the market.

Steel personnel doors with built in locking mechanism and hidden hinges.

The windows are protected by steel shutters, which are locked internally and can only be opened from inside the rest room.

These include sanitary conveniences, washing facilities, access to drinking water, accommodation for drying and changing clothes, and an area for rest and eating.

Groundhog welfare units are supplied with a current electrical installation test certificate.

| Dimensions | 7620mm(L) x 2755mm(W) |

|---|---|

| Unladen Weight | 4,300kg* |

| Possible Gross Weight | 4,600kg* |

| Generator | 9.8kVA |