The GPO600 Eco Fusion offers the legendary robustness and ease of use of the standard Groundhog Mobile welfare unit whilst offering a green environmental solution. Giving owners and end users savings by way of reduced fuel usage, reduction in generator servicing, longer generator life, fewer breakdowns and reduced noise pollution.

The Groundhog Eco Fusion mobile welfare unit are available in two other sizes: GP360 Fusion for six operatives; GP500 Fusion for 12-14 operatives.

The Fusion Mobile units from Groundhog are suitable for accommodating six persons, which provides pleasant and safe working environments, ideal for rental companies and contractors.

The Eco Fusion Mobile units from Groundhog offers the legendary robust and ease of use of the standard Groundhog GPO600 whilst offering a green environmental solution.

The GPO600 Eco Fusion is powered by an on board 12V battery enabling, the led lights, heating, hot water and inverter sockets (to charge lap tops, mobile phones and small printer) to be run without the need of the on board generator. The generator is only required to charge the onboard battery and run the hot water, kettle and microwave. The generator is fitted with an auto stop timer to save over running and unnecessary wastage.

GPO660 Fusion control panel with battery indicator allows the user to control the heater temperature. Included is an inverter powered single socket.

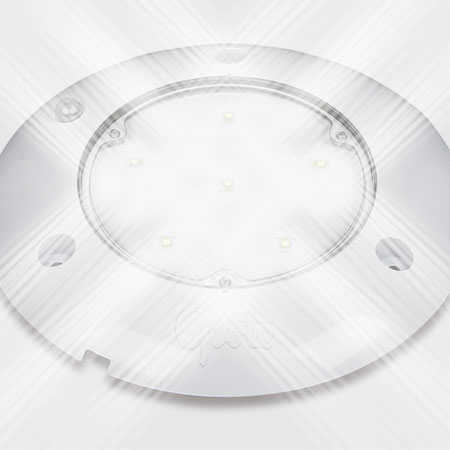

12V LED PIR lighting automatically senses movement turning lights on automatically. Situated in the canteen, toilet and generator room.

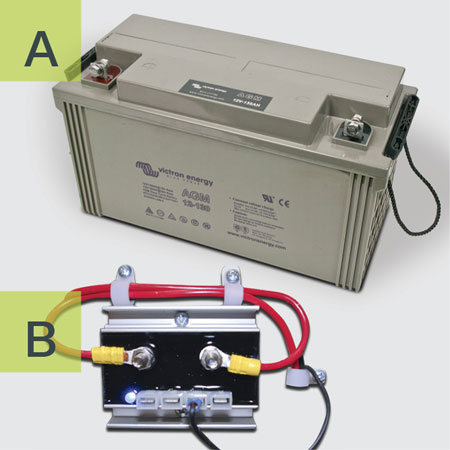

Pro Charge Ultra (a) charges the 130A/hr battery when the generator is running. The Battery Guard (b) prevents the excessive discharge of the battery and protects electronic appliances against undervoltage.

The air blown heating system does not require the generator to run continuously due to the on-board battery system saving on fuel and servicing costs. Heating outlets set in canteen and generator room.

GENERATOR PRODUCES POWER

GENERATOR PRODUCES POWER BATTERY STORES EXCESS POWER

BATTERY STORES EXCESS POWER NO WASTED POWER

NO WASTED POWER LESS FUEL USED

LESS FUEL USED COST SAVINGS ON FUEL USE

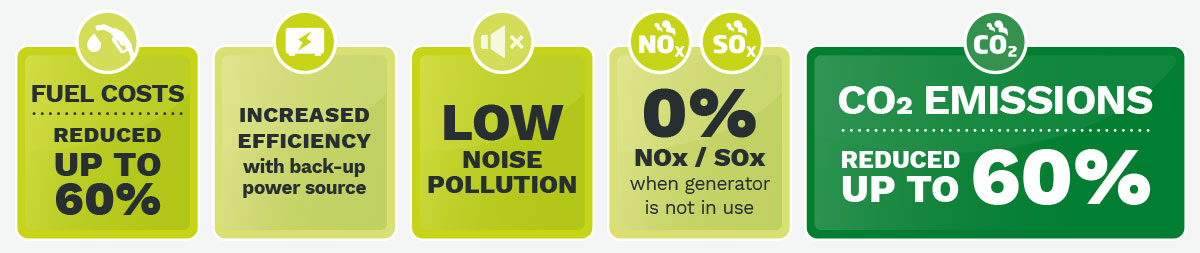

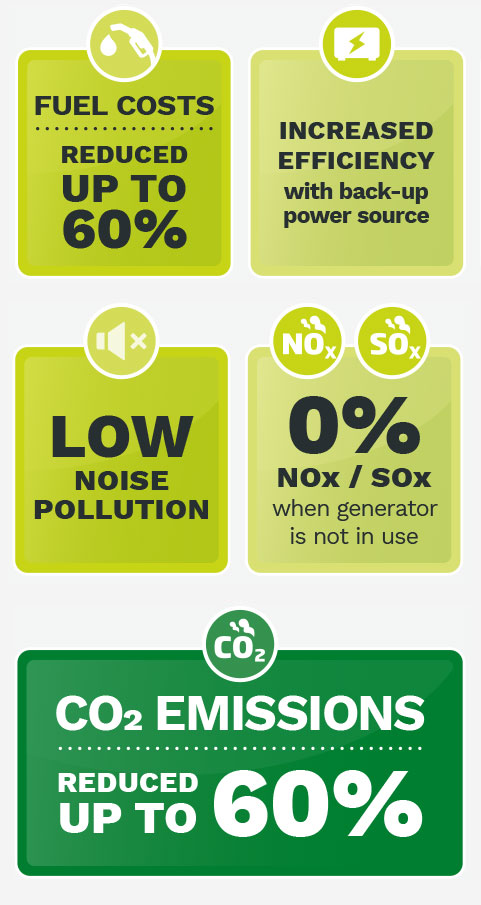

COST SAVINGS ON FUEL USEThe Eco Fusion Mobile units' environmental features give owners and end users savings by way of reduced fuel usage, 60% reduction in generator servicing, longer generator life, fewer breakdowns and massively reduced noise pollution.

Steel construction forms one of the most secure welfare units on the market.

Groundhogs unique lowering system which enables the unit to be secured at ground level when sited. This also enables a safe entry and exit by personnel without the requirement for steps.

Steel personnel doors with built in locking mechanism and hidden hinges.

The windows are protected by steel shutters, which are locked internally and can only be opened from inside the rest room.

The nosecone security cover is a swing operated hood which protects the towing coupling and once locked, prevents the unit from being removed off site.

Push button controls to lower front and rear hydraulic rams

Rams lift unit from ground ready to release axle pins

Unit is lowered and canopy locked to protect towing facility

These include sanitary conveniences, washing facilities, access to drinking water, accommodation for drying and changing clothes, and an area for rest and eating.

Groundhog welfare units are supplied with a current electrical installation test certificate.

| Dimensions | 6000mm(L) x 2300mm(W) |

|---|---|

| Dimensions Inc. Drawbar | 7320mm(L) x 2300mm(W)* |

| Unladen Weight | 2,500kg * |

| Possible Gross Weight | 3,500kg* |

| Generator | 6kVA |