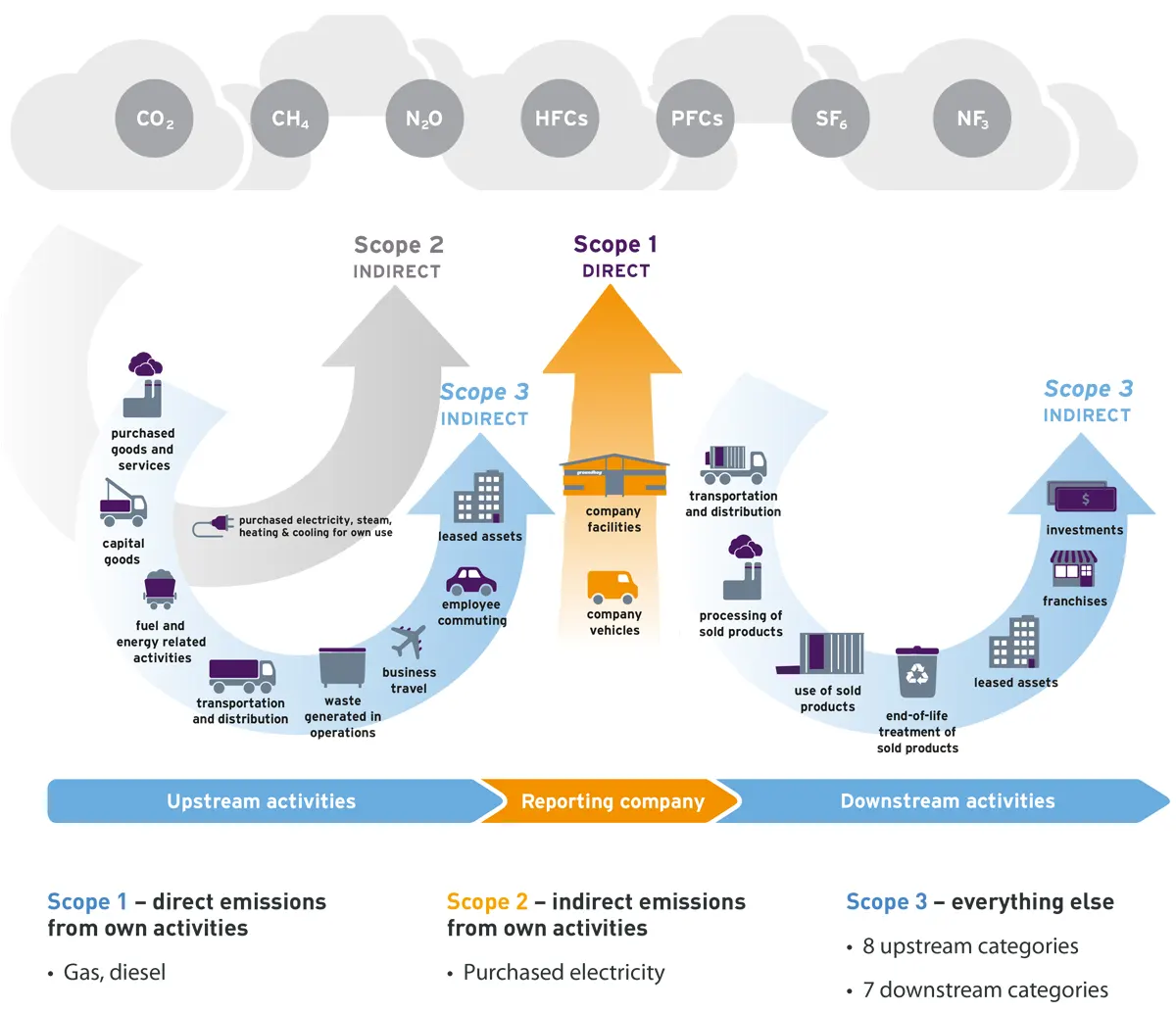

Many of our valued customers share these environmental ambitions and are actively working to reduce carbon emissions within their supply chains.

As responsible suppliers, we are dedicated to providing the support they need to achieve these goals. Groundhog have taken a significant step towards understanding and reducing our environmental impact by producing an indicative initial carbon footprint for our products.

We have colleagues from across the business engaged in our projects, with a particular focus on purchasing, design, operations and logistics.

We have been working for several years with Dr Gavin Milligan of Green Knight Sustainability Consulting, who assists with technical matters and supports our team in their projects as needed.

We work with key suppliers and partners to improve the accuracy of our carbon footprint calculations, identify opportunities for improvement and support innovation.

We know that reducing carbon is important to our customers and we work with them to ensure that we can provide them with the information they need. We also actively seek opportunities for collaboration to better understand the use phase of our products both to identify design improvement opportunities and operational improvements.

We are reviewing our designs to identify alternative fittings and materials of construction with lower environmental impacts.

We are investigating back up our supply chains looking for lower-impact sources, such as more efficient manufacturing processes.

Beyond materials, we are reviewing design for operational efficiency, deconstruction and material re-use.

We have compiled a set of simple guidance principles to aid our customers’ clients in getting the best carbon efficiency out of our products in everyday use.

We guarantee to buy back used Groundhog units enabling us to remanufacture where practicable or recover materials for re-use or controlled recycling.

Ecovadis is a widely recognised Environmental, Social and Governance (ESG) reporting platform, also used by some of our largest customers. They provide assessments based on documentation provided by applicants and provide guidance on improving policies and procedures to strengthen ESG performance. We have started our submission and have been awarded ‘Committed’ status; the next step is re-submission of updated documentation.

The Ecovadis assessment process is based on industry best practice, assuring our customers that we are working to the same standards as they are. The way the assessment works is comparative, meaning that accreditation levels can go down, even if the rating score goes up.

Our approach is to share relevant information with our customers and other key stakeholders, and visibility of our Ecovadis rating is a part of that commitment.

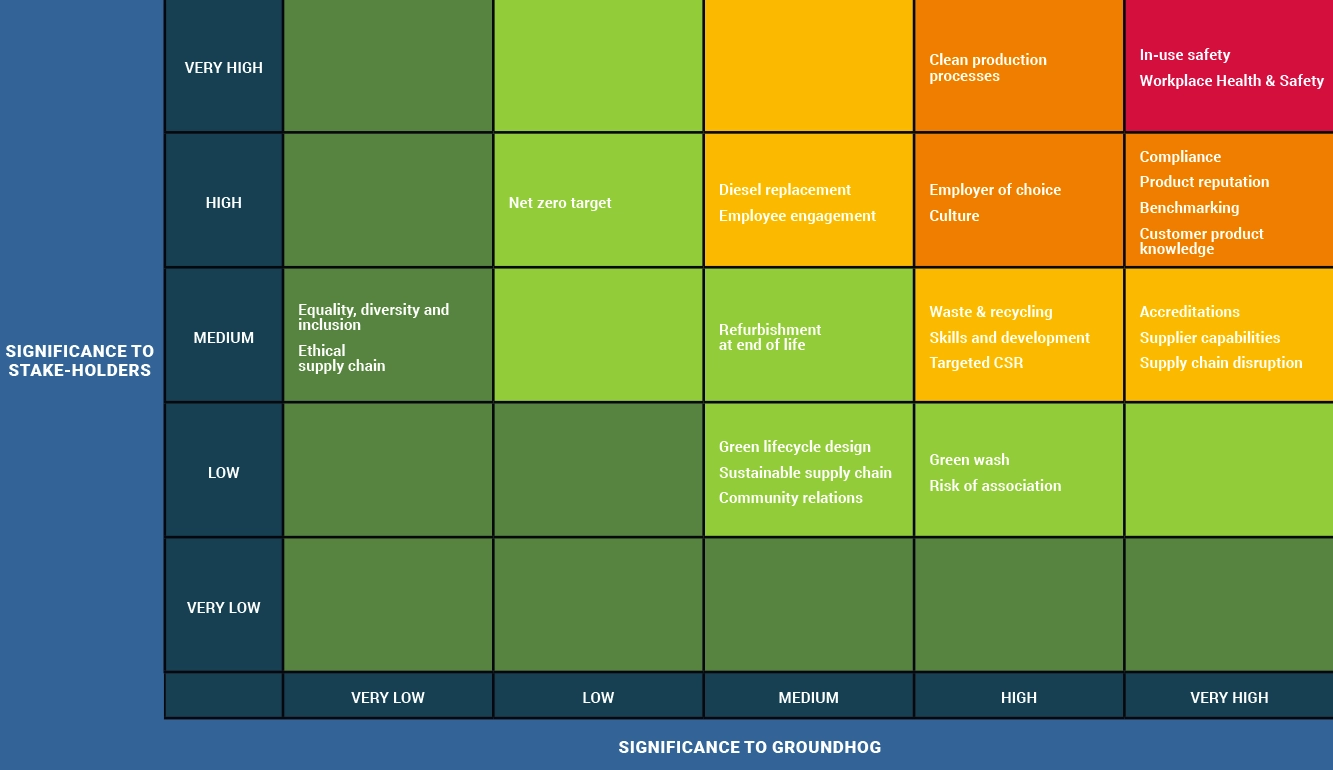

We reviewed the sustainability priorities of major customers and peer businesses along with current trends in ESG to arrive at a long list of potential issues. This was reduced to a short-list applying our internal expertise.

Colleagues from Procurement, Compliance, Design, Operations, Logistics, HR and Sales reviewed the issues short-list, facilitated by our expert advisor.

We assigned internal and stakeholder significance to each of the issues, agreeing on priority areas and assigning them to team members with relevant functional responsibilities.

Based on the materiality assessment conducted in 2025, our team, including members from Procurement, Compliance, Design, Operations, Logistics, HR, and Sales, engaged deeply with stakeholders to prioritize key ESG issues.

Based on the materiality assessment conducted in 2025, our team, including members from Procurement, Compliance, Design, Operations, Logistics, HR, and Sales, engaged deeply with stakeholders to prioritize key ESG issues.