The i500 twin toilet offers the legendary robustness and ease of use of the GP500 Fusion Pulse mobile welfare unit from groundhog whilst offering an enhanced green environmental solution. Offering up to 100% reductions in carbon emissions whilst on-board battery charger is not in use.

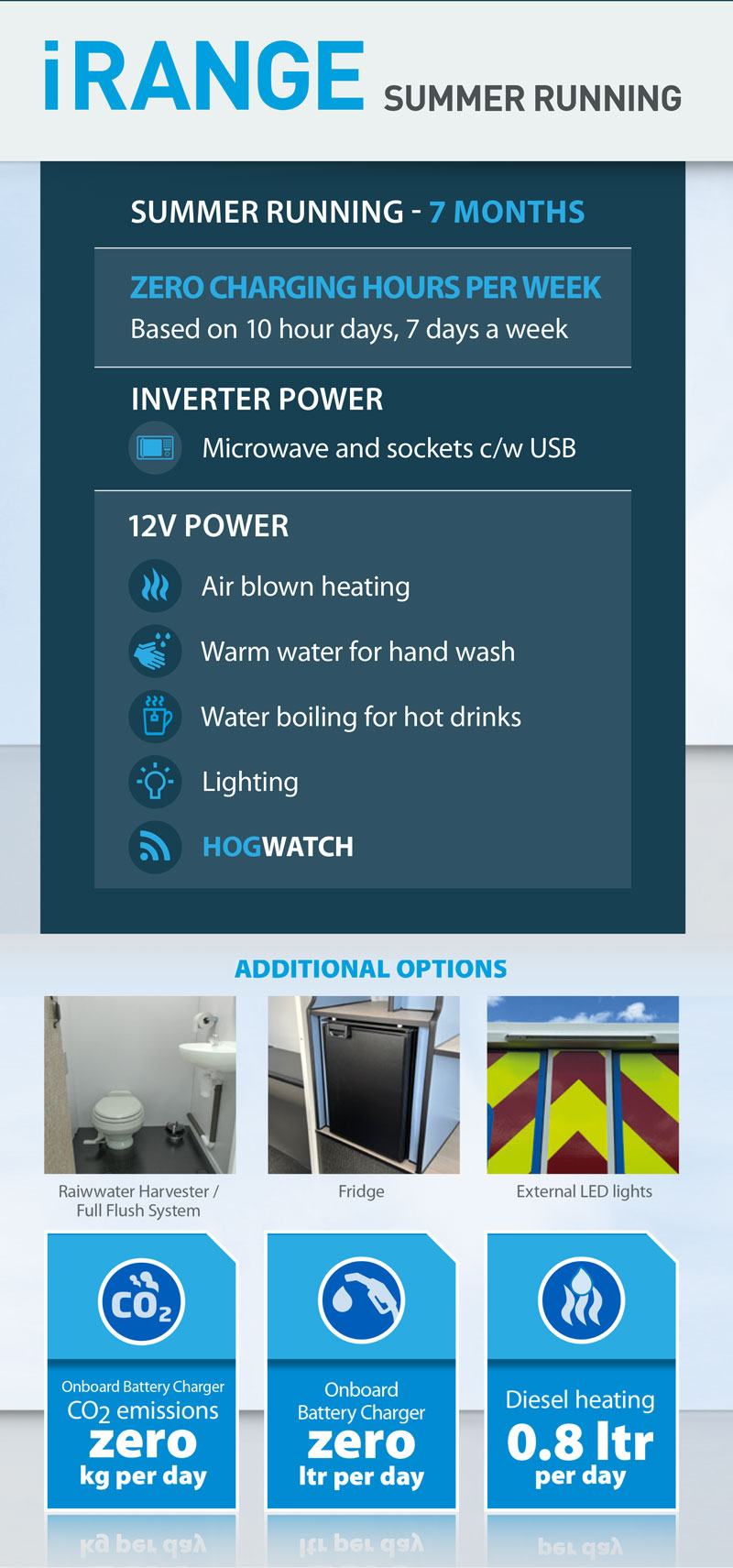

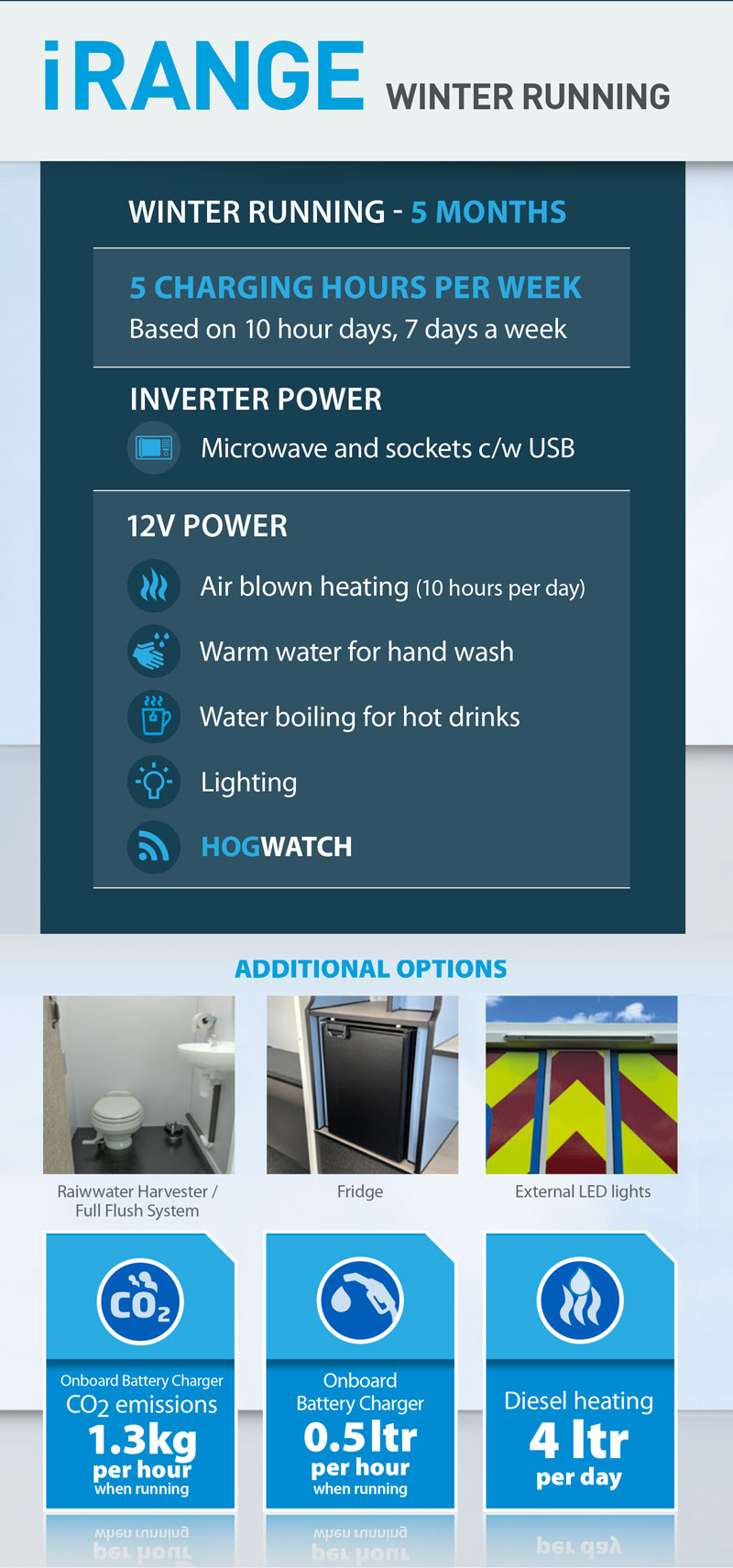

The i500 twin toilet is designed to run in summer months without the on-board battery charger running. During the winter period and night use the battery charger will still be required, with a reduction in running of up to 90% when compared to the fusion pulse welfare unit.

The unit has a compact overall size for towing, with a large spacious welfare area which can accommodate up to 12-14 people

- ideal for flexible on-site applications, helping you achieve realistic carbon reduction goals.

The iRange welfare units from Groundhog are suitable for accommodating twelve to fourteen persons, which provides pleasant and safe working environments, ideal for rental companies and contractors.

The iRange welfare units from Groundhog offers the legendary robust and ease of use of the fusion pulse Groundhog GPO500 whilst offering a green environmental solution.

The i500 Twin Toilet Mobile is powered by an on-board battery system enabling, all internal services to run without the need of the on-board battery charger. The on-board battery charger is only required to charge the batteries and starts and stops as and when battery levels dictate. Ensuring zero loss of power.

i500 control panel allows the user to operate the 12v system power including, air-blown heating, warm water for handwash & hot drinking water. The control panel also provides fuel, waste and fresh water tank levels. (Full flush models only)

12V LED PIR lighting automatically senses movement turning lights on automatically. Situated in the canteen, toilet and generator room.

The air blown heating and hot water system does not require the generator to run continuously due to the on-board battery system, saving on fuel and servicing costs. Heating outlets set in canteen and generator room.

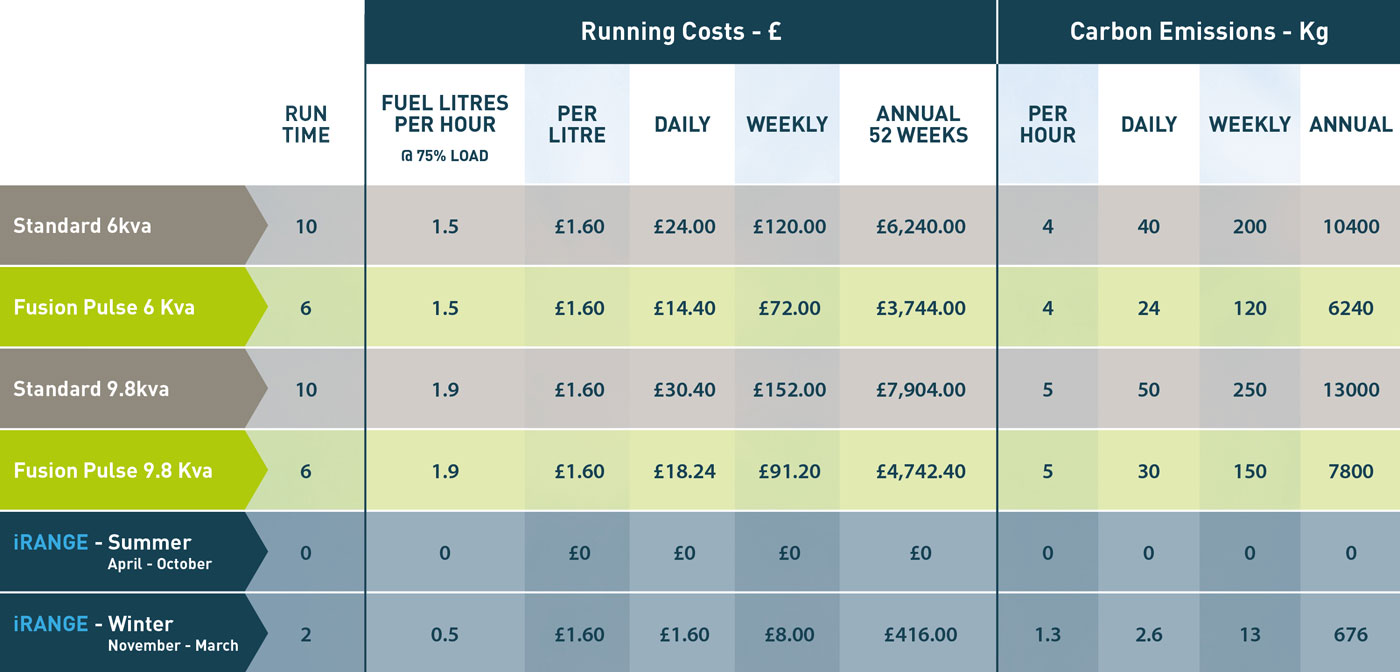

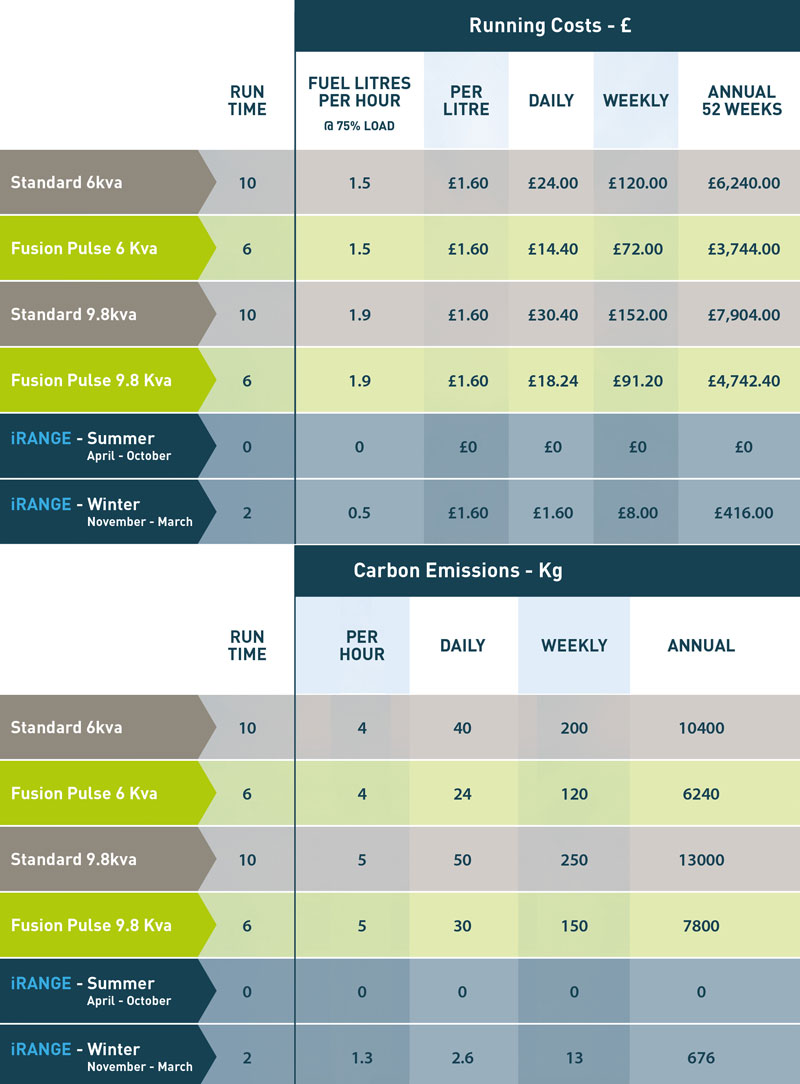

Figures based on units running 5 days per week 10hrs a day. Webasto heating systems will use between 0.1 and 0.2 L of diesel per hour depending on load. As an average it will use 0.1l per hour when in use.

The i500 is designed to run in summer months without the on-board battery charger running. During the winter period and night use the battery charger will still be required, with a reduction in running of up to 90% reduction when compared to the fusion pulse welfare unit.

Steel construction forms one of the most secure welfare units on the market.

Groundhogs unique lowering system which enables the unit to be secured at ground level when sited. This also enables a safe entry and exit by personnel without the requirement for steps.

Steel personnel doors with built in locking mechanism and hidden hinges.

The windows are protected by steel shutters, which are locked internally and can only be opened from inside the rest room.

The nosecone security cover is a swing operated hood which protects the towing coupling and once locked, prevents the unit from being removed off site.

Push button controls to lower front and rear hydraulic rams

Rams lift unit from ground ready to release axle pins

Unit is lowered and canopy locked to protect towing facility

These include sanitary conveniences, washing facilities, access to drinking water, accommodation for drying and changing clothes, and an area for rest and eating.

Groundhog welfare units are supplied with a current electrical installation test certificate.

| Length | 5000mm |

|---|---|

| Length (Inc. Drawbar) | 6320mm(L)* |

| Height (on wheels) | 2900mm(L)* |

| Height (on ground) | 2500mm(L)* |

| on-board battery charger | 2kVA |

| Unladen Weight | 2,600kg* |

| Possible Gross Weight | 3,000kg* |

| Solar Panel | x4 425 Watt |

| Fresh Water | x2 20 Litres |

| Waste Water | 50 Litres |

| Underfloor Toilet Waste Tank | 300 Litres |

| Toilet Water Tank (under seating) | 50 Litres |

| Fuel Tank | 32 Litres |

* Fully laden gross weight exceeds maximum towing capacity, unit should be transported to site prior to making site ready